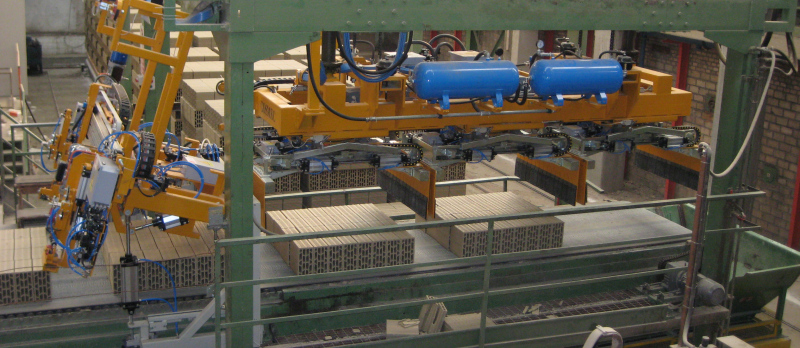

The cutting systems constructed by COSMEC excel in innovation, versatility and reliability of use.

COSMEC applies the most advanced motion control technologies which allow precise, coordinated and continuous movements thereby reducing machine wear and maintenance.

COSMEC provides a range of engineering solutions, including:

- Horizontal, vertical and horizontal/vertical slug cutters

- Electronic cutters with or without trimming

- Vertical cutters

- Brick cutter with chamfering

- Horizontal cutters

- Pass cutters

The devices can be equipped with various accessories, such as:

- Pneumatic wire tensioning

- Wire movement

- Pre-cutting on the middle of the piece

- Chamfering.

- Device for creating side opening.